Lab and Teaching Materials

To ensure that our undergraduate programs are qualified, the following facilities that have been assembled:

- Computer and References Room

- Strength of Materials Laboratory

The strength of materials laboratory is to demonstrate the basic principles in the area of strength and mechanics of materials and structural analysis to the undergraduate students through a series of experiments. The students are also introduced to the data acquisition system (Strain gauges and dial gauges etc) used in experimental study.

List of Equipment

- Universal Material Testing Unit

- Thin Cylinder Unit

- Brinell Hardness Testing Unit

- “Brinell, Vickers and Rockwell Hardness

- Testing Unit”

- Shear Force & Bending Momentum Unit

- Charpy & Izod Impact Testing Unit

- Computer Controlled Fatigue Testing Unit

- Twist and Bend Machine

- Beam Deflection Unit

- Torsion Unit

- Unit for studying Hooke’s law

- Torsional Oscillations Unit

- Strain Gauge Training Unit

- Unit for determining the gauge factor of strain gauges

- Creep Testing Unit

- Impact load Test (Wp-400) Germany

- Torsional Stress Test (WP-500) Germany

- Tension Test (CC India)

- Compression Test (WP- 300) Germany

- Hydraulic Press (30 ton)

- Hardness Tester Machine (TRB – 250) India

3. Applied Mechanics Laboratory

The applied mechanics laboratory is used for undergraduate teaching. Students have the opportunity to use experimental apparatus and compare results against that of accepted theory, developing and enhancing their knowledge of important scientific concepts.

List of Equipment

- Free Vibration Unit

- Free & Forced Vibration Unit

- Deflection of Curved Bars Unit

- Simple Balancing Unit

- Unit for Studying Free Vibration of a Bar

- Unit for studying Forces in a Simple Bar Structure

- Unit for studying Forces in Different Single Plane Trusses

- Unit for studying Forces in an Over determinate truss

- Unit for studying Deformation of Trusses

- Computer Controlled Torsional Vibration Unit

- Acceleration of Geared System Unit

- Unsymmetrical Cantilever Unit

- Simple Stability Problems Study Unit

- Loading of Struts Unit

- Suspension Bridge Unit

- Parabolic Arch Unit

- Three-Hinged Arch Unit

- Strut Bucking Unit

- Governor (CC India)

4. Automobile Engineering Lab

The automobile engineering laboratory is to provide students a good environment to understand the technology know-how, testing, service and set-up of modern motor vehicles for undergraduate projects.

List of Equipment

- Diesel Engine Trainer (YES – 01)

- Automotive Electronic Ignition System

- Chassis Trainer Unit (VB Italy)

- 2C Diesel Engine (Toyota D – turbo) Japan

- KUBOTA Engine (KND 5B) Myanmar

- “Four Stroke cycle air cooled 18hp china, S-1100T”

- Diesel Engine Fuel Injection (OPEC 119) (CAV DPA) Japan

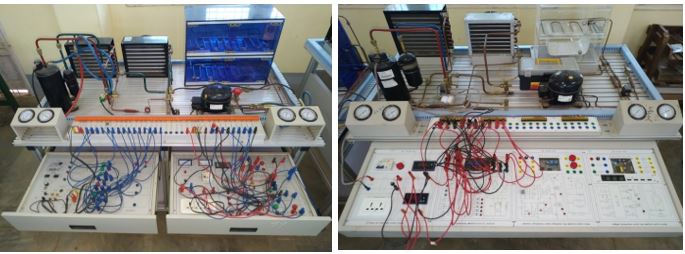

5. Refrigeration and Air-Conditioning Laboratory

The Refrigeration and Air Conditioning Laboratory is to learn about refrigeration and air-conditioning cycles and their performance under different operating conditions. Students also learn different psychrometric processes associated with air conditioning systems.

List of Equipment

- Air Conditioning and Refrigeration Training Set

- Modern Air-Conditioning and Refrigeration System Trainer

6. Machine Shop

Several intermediate performance objectives and corresponding criterion measures are listed for each of 11 terminal objectives for basic machine shop course. Titles of the 11 performance objectives are the following: Safety (housekeeping, equipment, clothing, handtools); measurement (micrometer, calipers, scale, vernier); layout (centering); lubrication (machines, handtools); benchwork (chipping, filing, scraping); cutting tools; surface grinder; grinder (hand); drill press; band saw; and lathe.

List of Equipment

- Lathe (Japan) TSL-360N

- Lathe (Myanmar) Industry 2

- Column Drilling Machine (Myanmar) BST-23

- Bench Drilling Machine (China) ZQ-4113

- Cutter Grinding Machine (CG-7) Japan

- Shaper Machine (Myanmar)

- KWANG CHOW C 6232 A(China)

- SHUN SHIN (China)

- GEMCO (Holland) Vertical spindle

- GEMCO (Holland) Horizontal Spindle

- Cylinder Polishing Machine (BS-2408 G)

- Boring Machine (Vertical) OPEC 101 CPS No A (Taiwan)

- Hand Press Cutting M/C (Pulley Type, High Speed Cutter)

7. Welding Shop

The student should be able to describe Measuring, Marking, Cutting, Sawing, and Filing, Drilling/Counter sinking, Threading tools / instruments, their uses & Safety and Personal safety. The student should be able to determine Arc Welding processes, tools and equipment, their use and safety. And then the student should be able to express the suitable welding joints, welding positions, Electrodes, their use and selection.

List of Equipment

- Welding Machine (Power Master)

- Welding Machine (Thailand) SRMK 500 Amp

- Portable Welding Machine (Thailand) MMA 200 D

- Welding Machine (YK – 255 Fl- 3) Japan